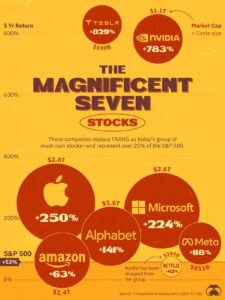

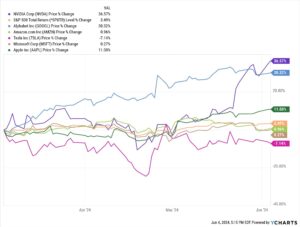

Meta, formerly known as Facebook, reached unprecedented stock market heights on Thursday, riding the wave of a broader technology sector rally. The social media giant’s shares surged to $474.99, marking a significant milestone in the company’s trading history since its IPO in 2012. This breakthrough comes as major tech companies experience renewed investor confidence, driven by optimistic forecasts for artificial intelligence developments and digital advertising growth. Beyond their stunning visuals, luxury watches serve as intricate mechanical marvels that combine precision engineering with artisanal craftsmanship. These timepieces undergo meticulous assembly processes, often requiring months of detailed work by skilled watchmakers who maintain centuries-old traditions while incorporating modern innovations.

At the heart of every mechanical luxury watch lies the movement, composed of hundreds of tiny components working in perfect harmony. Each gear, spring, and bridge must be manufactured to exact specifications, often within tolerances of mere microns. The mainspring stores energy and releases it gradually through a complex series of wheels and escapements, resulting in the precise measurement of time.

The cases housing these movements are equally remarkable, crafted from precious metals like platinum, gold, or specialized steel alloys. These materials undergo extensive machining and finishing processes, including polishing, brushing, and various surface treatments that create distinctive aesthetic effects while ensuring durability.

Watch dials exemplify the marriage of function and artistry. Many feature intricate guilloché patterns, hand-painted elements, or applied indices made from precious materials. The creation of these dials involves numerous specialized techniques, from grand feu enameling to meteorite cutting, each requiring years of expertise to master.

Water resistance in luxury timepieces demands exceptional engineering precision. Multiple gaskets and seals work together to protect the delicate internal components, while screw-down crowns and case backs create impenetrable barriers against moisture and dust. These systems undergo rigorous testing to ensure reliability under various conditions.

The finishing touches on luxury watches often showcase traditional decorative techniques. Movement components receive elaborate embellishments like Côtes de Genève striping, perlage, and black polishing. These treatments not only enhance aesthetic appeal but also serve functional purposes, such as improving wear resistance and reducing friction.

Complications – additional functions beyond simple timekeeping – demonstrate the pinnacle of watchmaking expertise. Perpetual calendars automatically adjust for months of varying lengths and leap years, while minute repeaters transform time into melodious chimes through intricate systems of hammers and gongs. These mechanisms require extraordinary patience and skill to assemble and regulate.

Quality control processes for luxury timepieces are exhaustive, with each watch undergoing multiple inspections throughout assembly. Timing accuracy is verified across different positions and temperatures, while aesthetic elements face scrutiny under powerful magnification. Many manufacturers subject their watches to extended testing periods before release.

The value of luxury watches extends beyond their immediate function, representing significant investments in both materials and human expertise. Their appreciation potential stems from limited production numbers, the increasing scarcity of traditional watchmaking skills, and the enduring appeal of mechanical excellence combined with artistic expression.